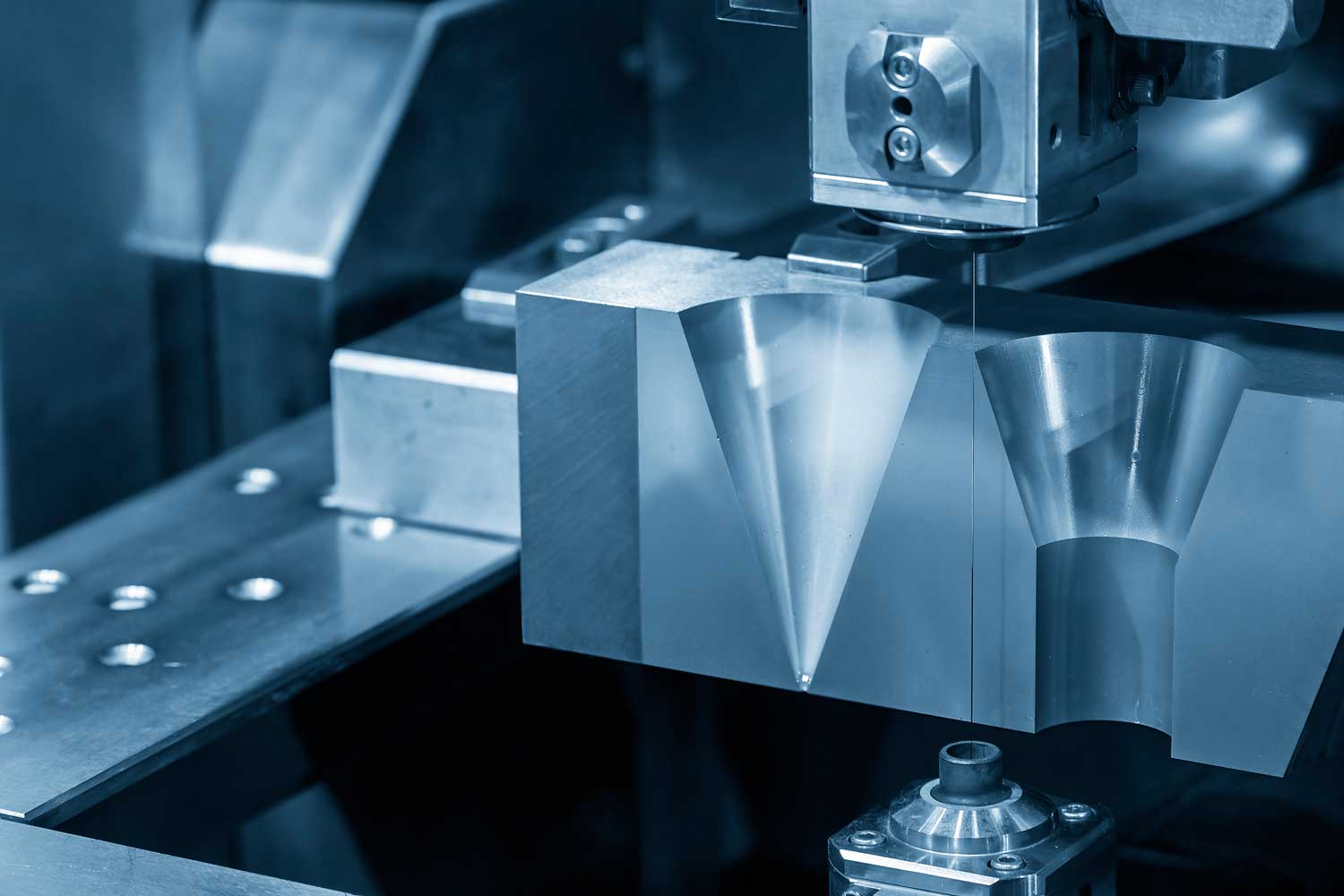

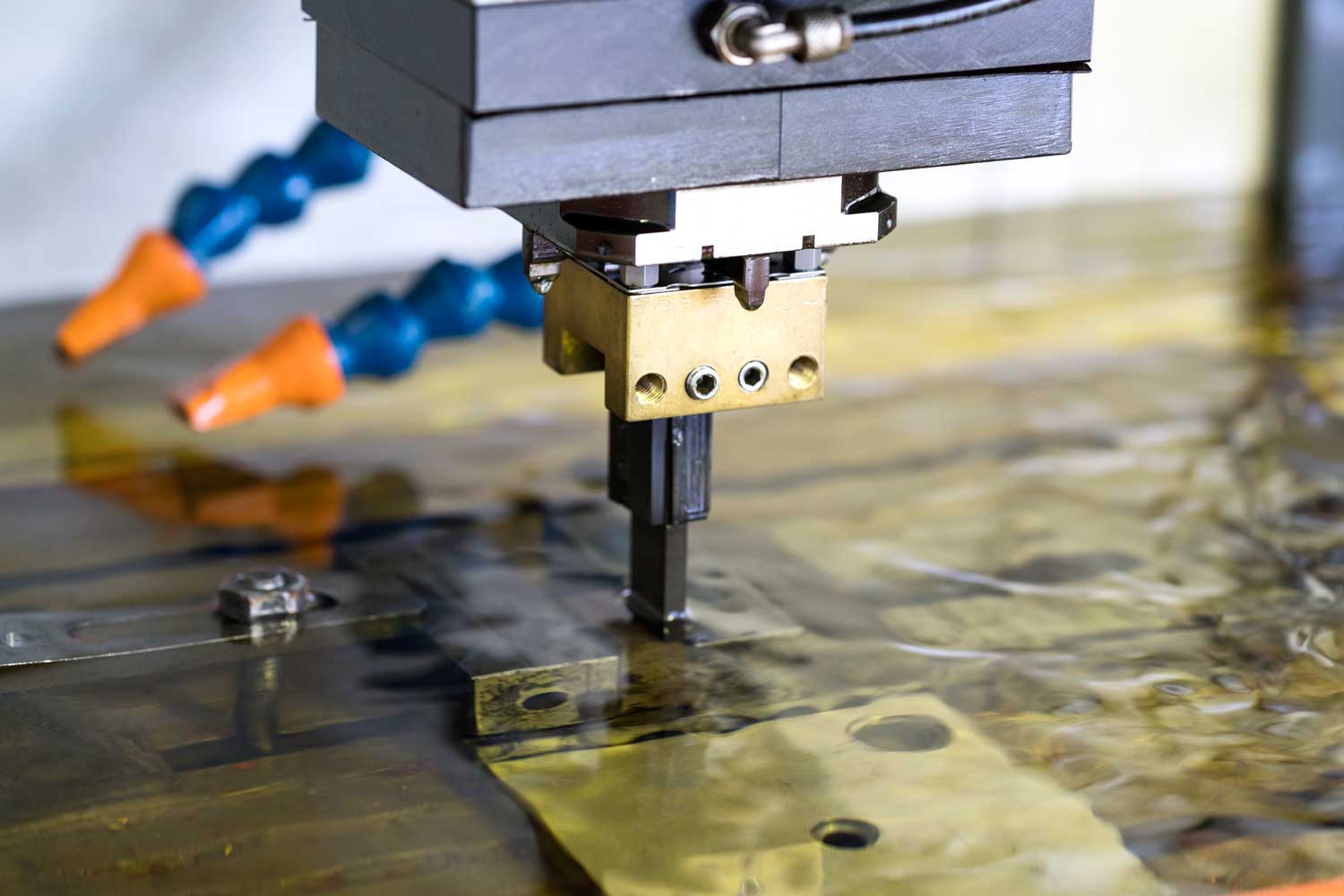

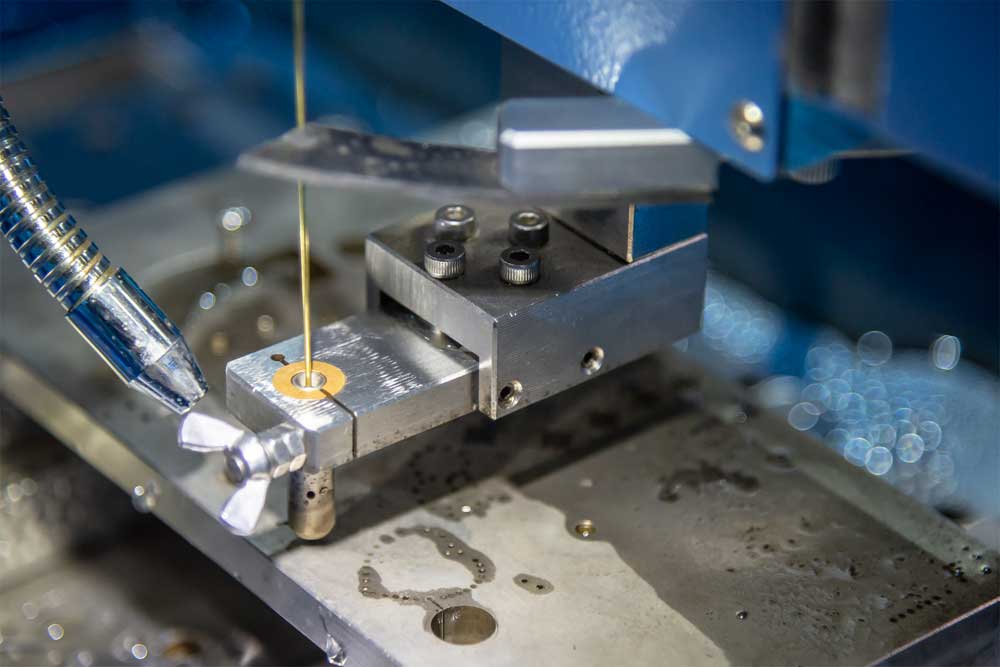

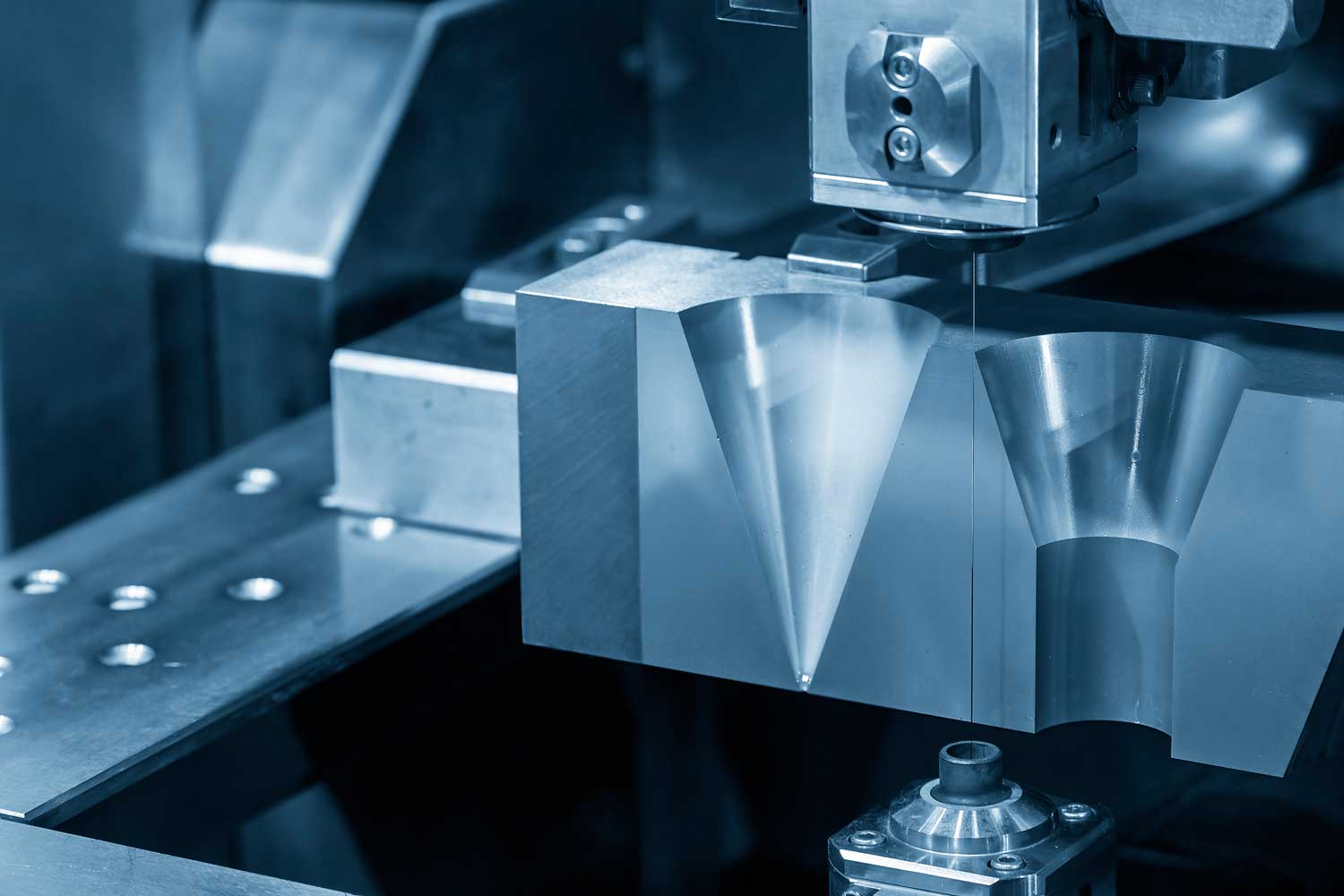

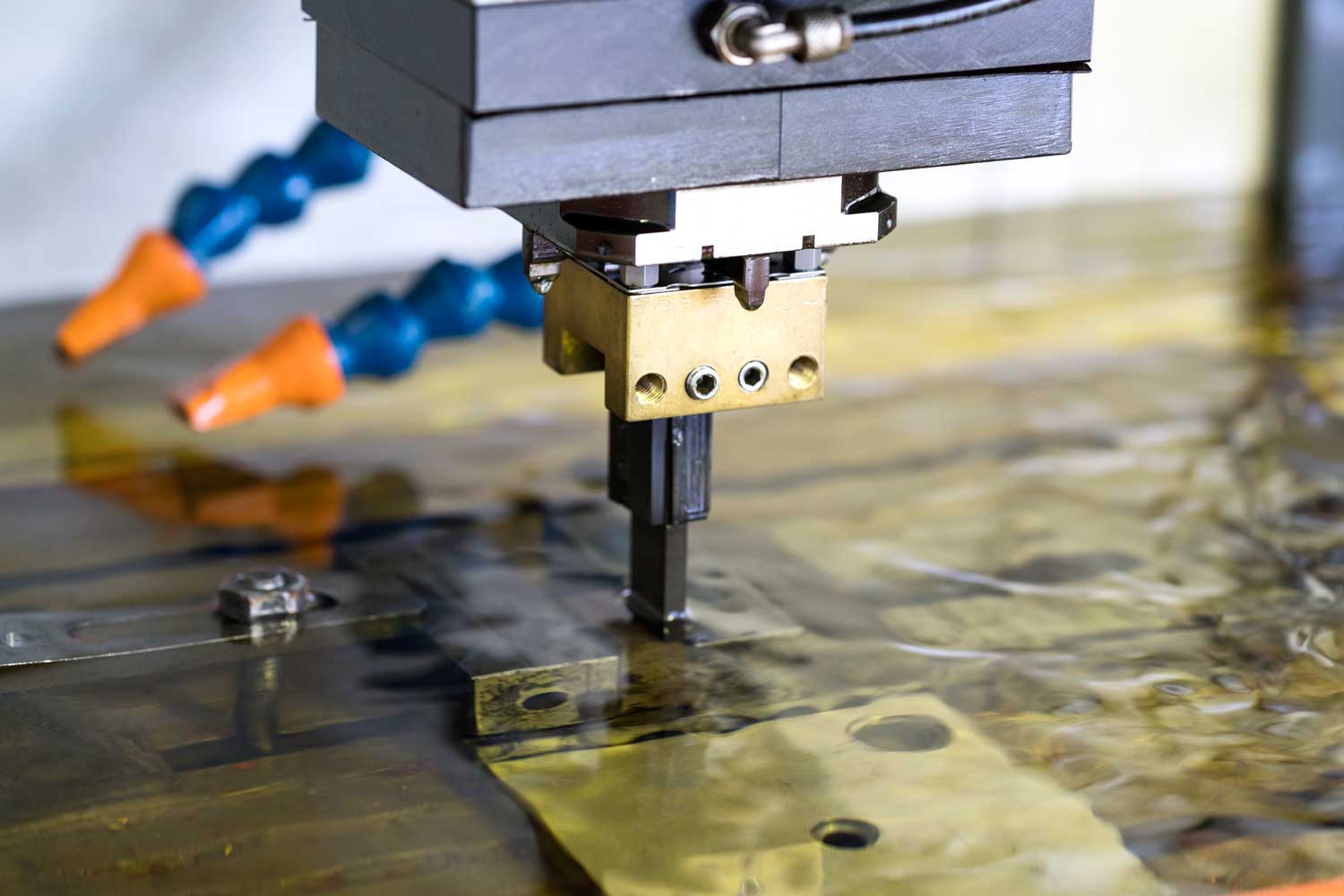

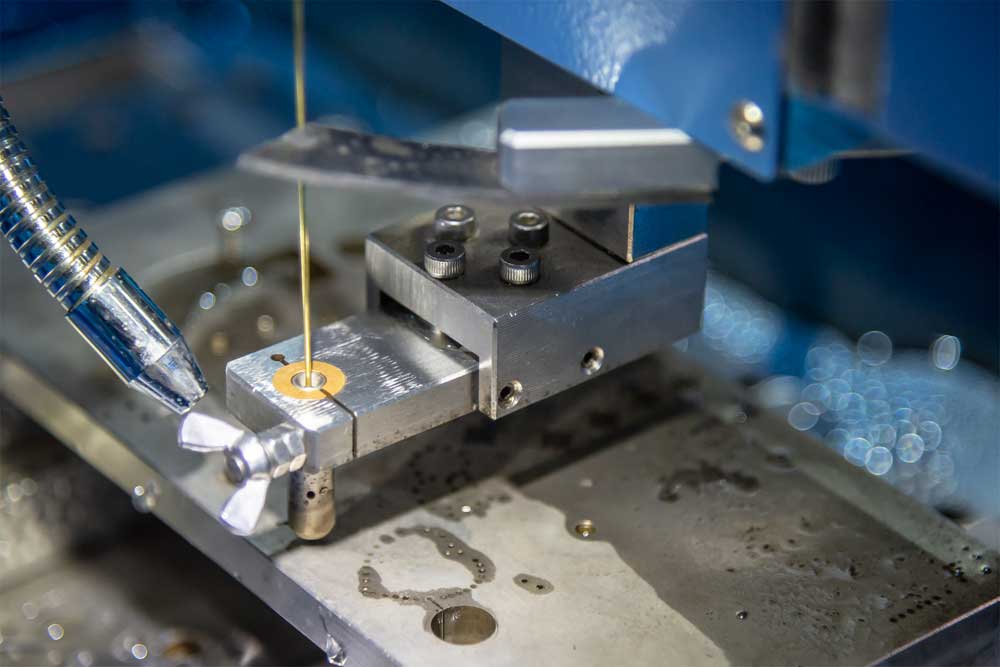

Since the company was established in 1997 we have specialised in wire erosion. Our workshop houses state of the art Mitsubishi wire eroding machines utilising the most advanced EDM technologies.

The machine operatives are highly skilled with a wealth of experience & knowledge in the field.

Wire erosion is a stress free method of removing material, which allows us to process materials that would otherwise be extremely difficult to machine. We are able to cut a range of conductive materials such as Aluminium, stainless steel, titanium, hardened tool steel, Inconel & Carbide, while working to extremely accurate tolerances (up to 4 microns)

Our machines offer varied capacity 24 hours a day, 7 days a week with our largest machine able to accommodate a workpiece height of up to 510mm.