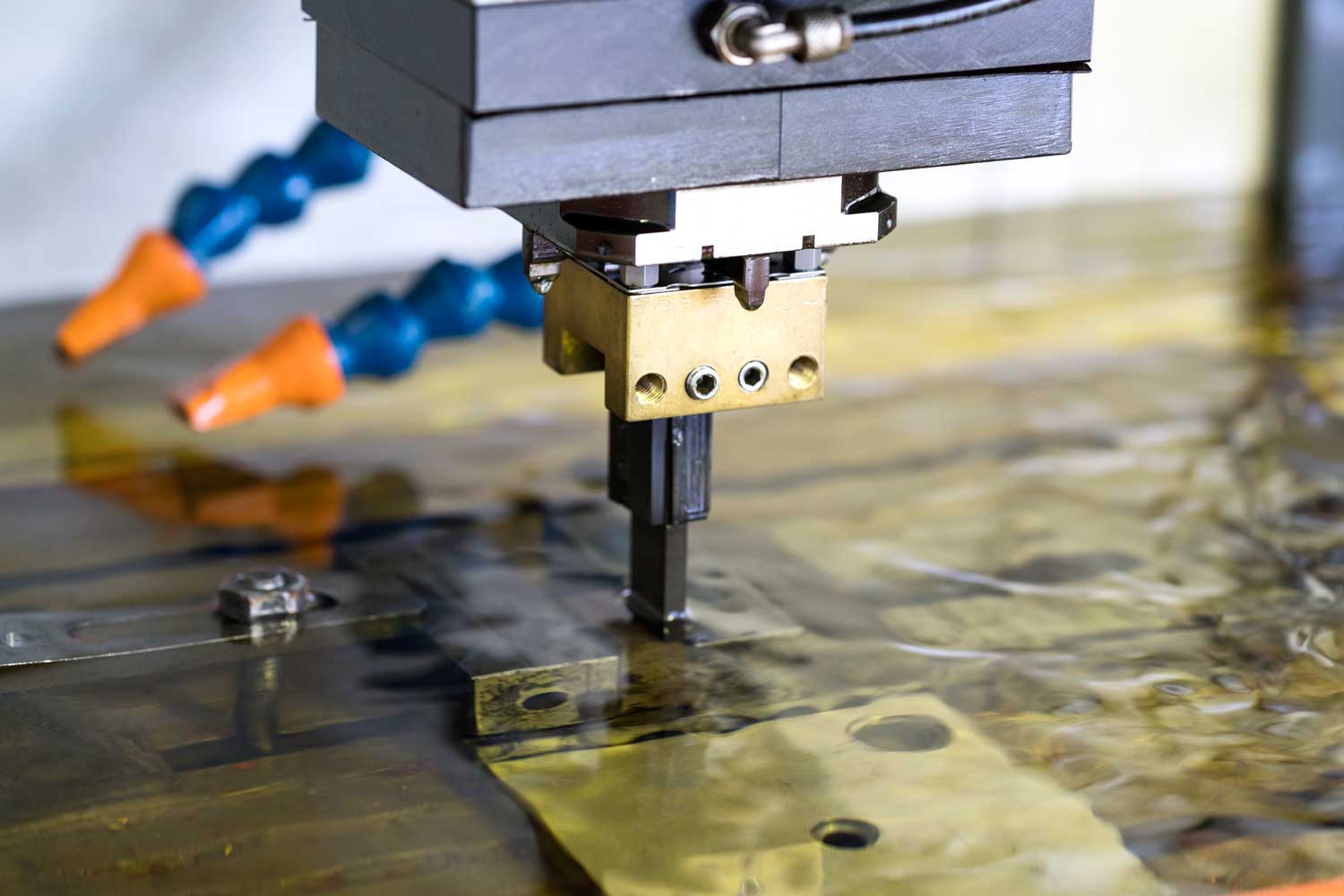

WIRE EROSION

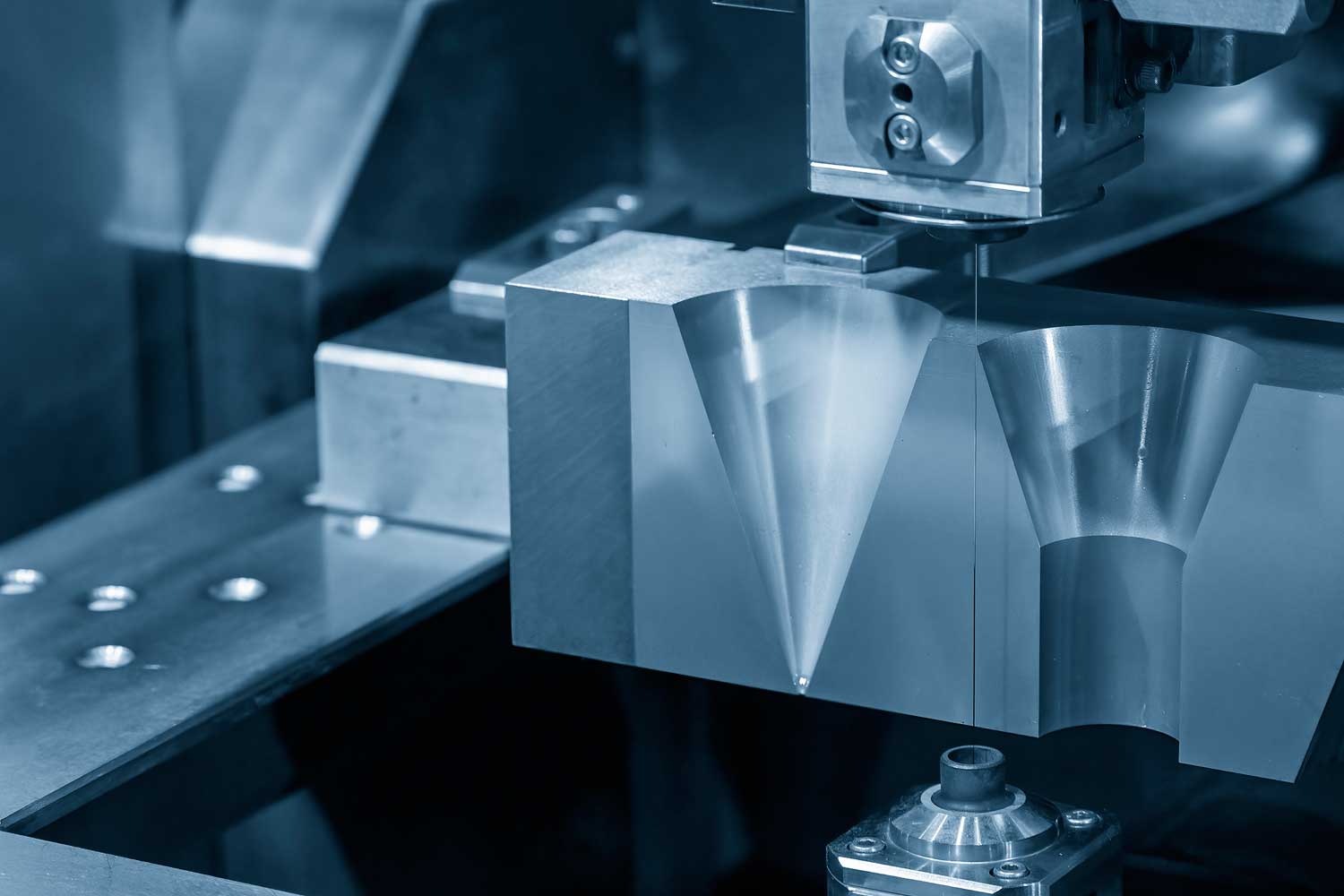

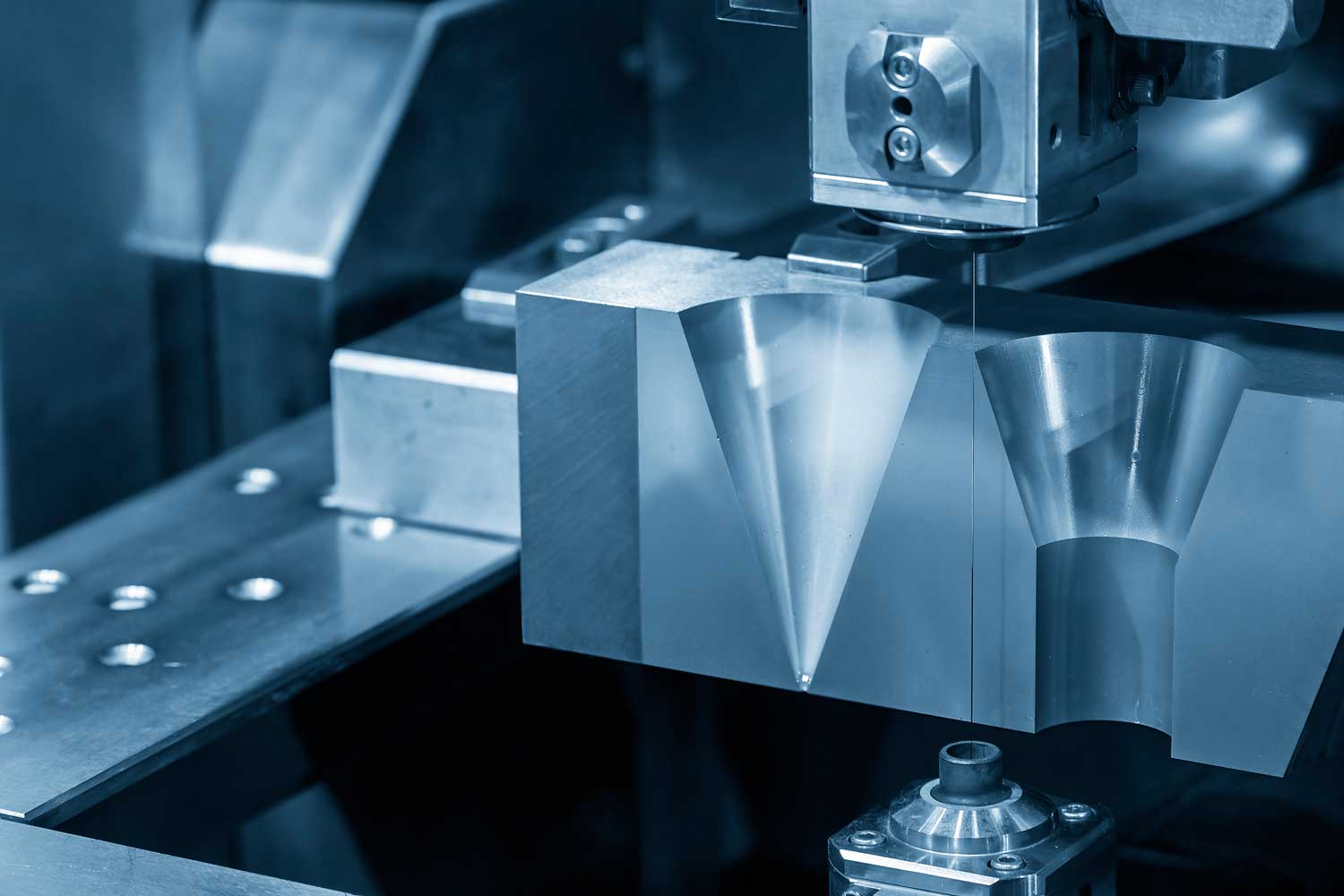

SPARK EROSION

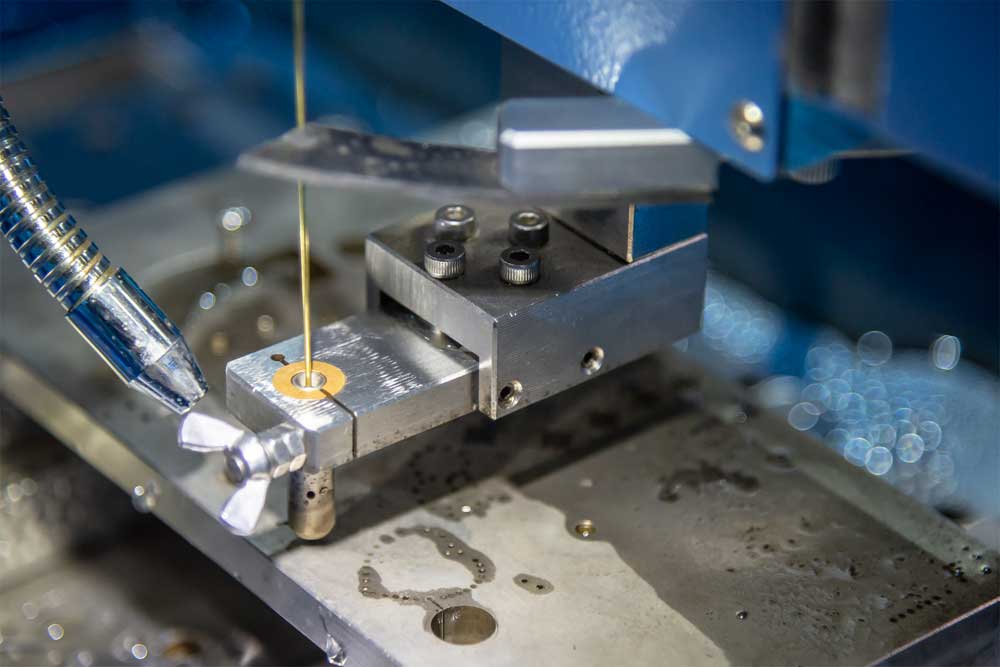

EDM HOLE DRILLING

CNC MACHINING

WHAT WE OFFER

- Full EDM capacity

- 7x wire eroding machines

- 4x Spark eroding machines

- 3x EDM drilling machines

- CNC milling services

- Capacity available 24 hours a day 7 days a week

- A fully equipped CAD/CAM department

- Full inspection services

- ISO 9001: 2015 certification

- Advanced materials

- Short lead times

- Competitive prices